Background and Challenges

In the past, the monitoring of pumping station was started or stopped by manual work, misoperation and untimely operation happened frequently. For example, the previous control mode cannot be real-time and accurate monitoring the parameters, like water level, gas concentration or something else, which lead to start on or off the pump, and even lead to the accident. Pumping station wireless monitoring system can realize wireless remote monitoring and control, without manual operation, save a lot of labor cost on maintenance and material resources, greatly improve the Factor of safety.

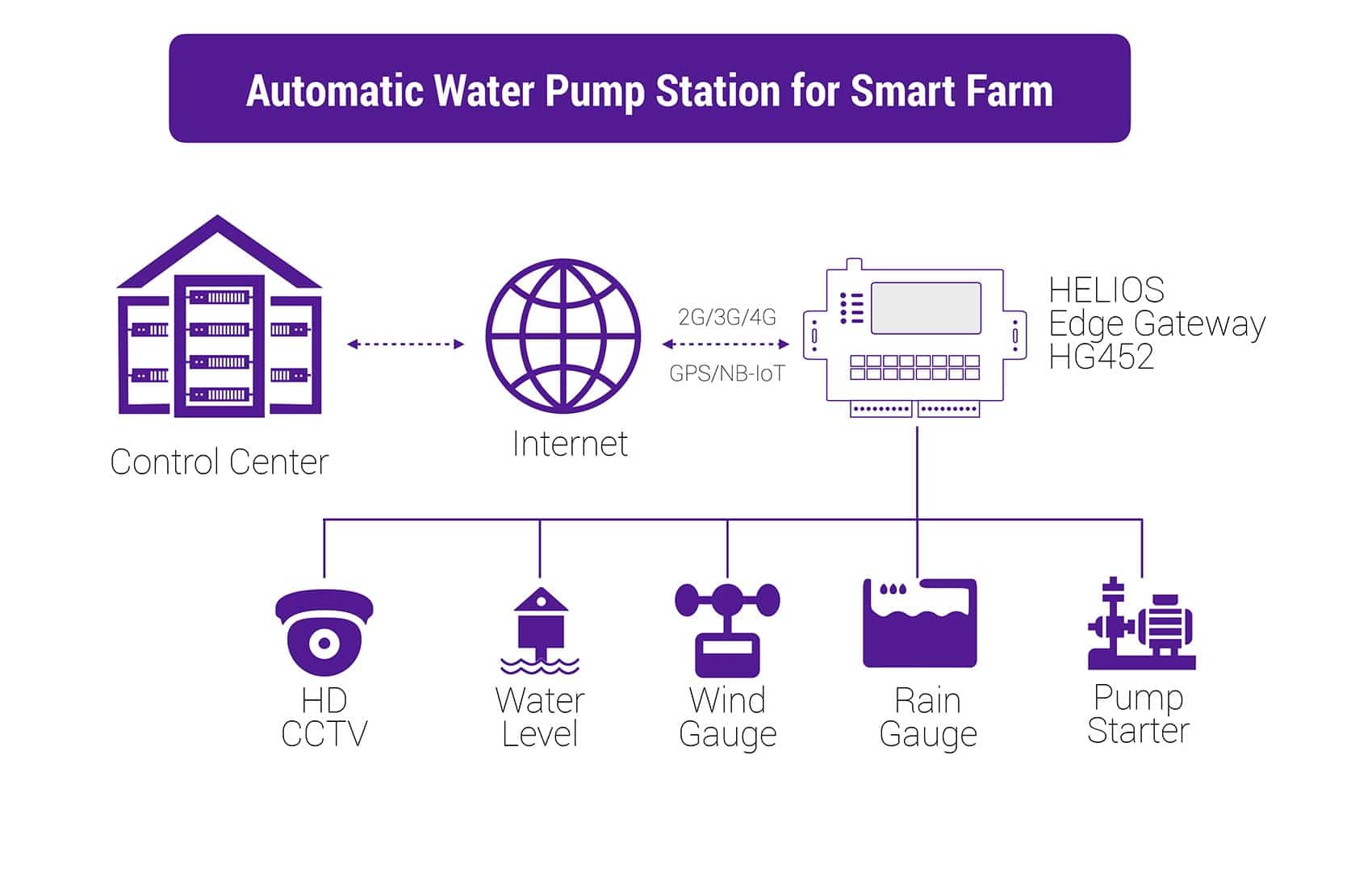

System Architecture

The system mainly adopts wireless 4G (LTE/LTE CAT M1/LTE-M/NB-IoT)/3G/GSM/GPRS technology to monitor water level, gas concentration, currency, voltage, etc., to monitoring the pump’s real-time working status. All the data are transparent transmission to remote data server or cloud IoT platform for analyzing via Modbus/Python/MQTT protocol. The entire solution consists of three major parts: field devices, wireless data transmission, central data monitoring. The field device is mainly adopting PLC for real-time acquisition of motor current, voltage and other operating parameters or water level data, to implement wireless on or off control on motor. The wireless data transmission is using HELIOS industrial 4G/3G/GPRS/GSM modem or routers which helps operators save a lot of cable costs, labor cost, civil construction costs and maintenance cost. Remote data server center or cloud IoT platform for scheduling and analysis; Mainly responsible for the analysis and management of the original data, and system analysis results display, processing.

Benefits

- To achieve real-time monitoring of the pump station to ensure the normal operation of the pump.

- Realization of remote start-stop control of machine pump.

- Multi-level Monitoring, management and superior departments synchronous monitoring.